Number of views:

1000

Indian and Pakistani law

Category: Product Center

Retail price

0.0

元

Market price

0.0

元

Number of views:

1000

Product serial number

Quantity

-

+

Stock:

0

Product description

Parameters

The INBA water slag process originated from the Belgian Sidmar Steel Company, and the first set was successfully developed and applied in the company.

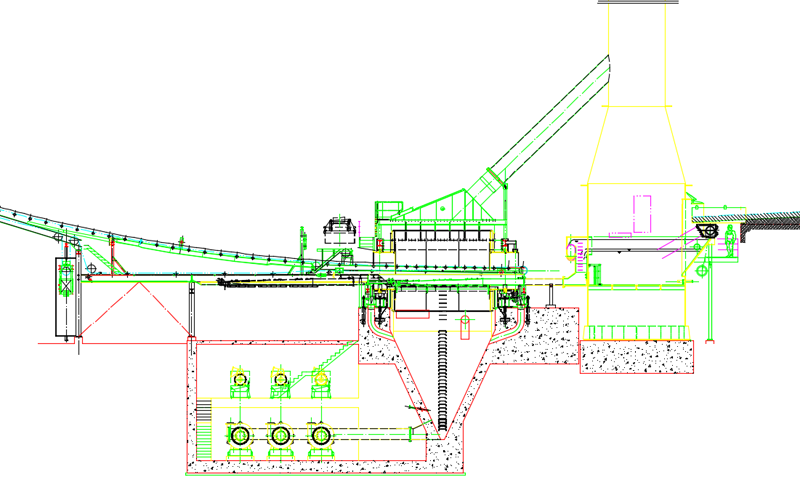

Process flow: The blast furnace slag flows into the granulation tower along the slag ditch, and is crushed by the pressurized, high-speed, slag-washing water sprayed by the granulator, soaked in the slag-washing water in the granulator, and quenched into granular water. The slag and the mixture of slag and water produced by granulation flow into the distributor through the diversion groove and are evenly distributed in the rotary dewatering drum; the slag washing water relies on gravity to pass through the filter screen of the dewatering drum and fall vertically into the lower inclined plate sedimentation tank; The water slag rotates to the highest point with the drum, and falls vertically into the center belt conveyor of the drum by gravity to be transported out; The water slag is transported by belt to the slag yard for loading and transportation. The water and fine slag enter the inclined plate sedimentation tank under the drum through the filter screen. After the fine slag is precipitated, it is pumped to the granulation tower by the water pump, and the overflow water of the inclined plate sedimentation tank flows into the hot water tank through the hot water tank. The water pump is lifted to the cooling tower for cooling, and then the slag is pumped to the granulator for continuous slag washing and recycling.

Process features: granulation tower, diversion tank, distributor, dehydration drum, internal belt conveyor, sedimentation tank, hot water tank, hot water pump, cooling tower, cold water pool, slag flushing pump, and slag flushing pipeline.

Schematic diagram of the process of India and Pakistan (INBA)

Keyword:

law

the

water

and

slag

to

tank

is

into

by

Previous

Indian and Pakistani law

客户留言

Description:

Related Products

Indian and Pakistani law

The INBA water slag process originated from the Belgian Sidmar Steel Company, and the first set was successfully developed and applied in the company.

Process flow: The blast furnace slag flows into the granulation tower along the slag ditch, and is crushed by the pressurized, high-speed, slag-washing water sprayed by the granulator, soaked in the slag-washing water in the granulator, and quenched into granular water. The slag and the mixture of slag and water produced by granulation flow into the distributor through the diversion groove and are evenly distributed in the rotary dewatering drum; the slag washing water relies on gravity to pass through the filter screen of the dewatering drum and fall vertically into the lower inclined plate sedimentation tank; The water slag rotates to the highest point with the drum, and falls vertically into the center belt conveyor of the drum by gravity to be transported out; The water slag is transported by belt to the slag yard for loading and transportation. The water and fine slag enter the inclined plate sedimentation tank under the drum through the filter screen. After the fine slag is precipitated, it is pumped to the granulation tower by the water pump, and the overflow water of the inclined plate sedimentation tank flows into the hot water tank through the hot water tank. The water pump is lifted to the cooling tower for cooling, and then the slag is pumped to the granulator for continuous slag washing and recycling.

Process features: granulation tower, diversion tank, distributor, dehydration drum, internal belt conveyor, sedimentation tank, hot water tank, hot water pump, cooling tower, cold water pool, slag flushing pump, and slag flushing pipeline.

Indian and Pakistani law

The INBA water slag process originated from the Belgian Sidmar Steel Company, and the first set was successfully developed and applied in the company.

Process flow: The blast furnace slag flows into the granulation tower along the slag ditch, and is crushed by the pressurized, high-speed, slag-washing water sprayed by the granulator, soaked in the slag-washing water in the granulator, and quenched into granular water. The slag and the mixture of slag and water produced by granulation flow into the distributor through the diversion groove and are evenly distributed in the rotary dewatering drum; the slag washing water relies on gravity to pass through the filter screen of the dewatering drum and fall vertically into the lower inclined plate sedimentation tank; The water slag rotates to the highest point with the drum, and falls vertically into the center belt conveyor of the drum by gravity to be transported out; The water slag is transported by belt to the slag yard for loading and transportation. The water and fine slag enter the inclined plate sedimentation tank under the drum through the filter screen. After the fine slag is precipitated, it is pumped to the granulation tower by the water pump, and the overflow water of the inclined plate sedimentation tank flows into the hot water tank through the hot water tank. The water pump is lifted to the cooling tower for cooling, and then the slag is pumped to the granulator for continuous slag washing and recycling.

Process features: granulation tower, diversion tank, distributor, dehydration drum, internal belt conveyor, sedimentation tank, hot water tank, hot water pump, cooling tower, cold water pool, slag flushing pump, and slag flushing pipeline.

Indian and Pakistani law

The INBA water slag process originated from the Belgian Sidmar Steel Company, and the first set was successfully developed and applied in the company.

Indian and Pakistani law

The INBA water slag process originated from the Belgian Sidmar Steel Company, and the first set was successfully developed and applied in the company.

National Service Hotline:

13405568899

Phone: 13405568899

E-mail: 827352855@qq.com

Website: www.yzshunda.com.cn

Mobile Website

Copyright: Yangzhou Shunda Technology Co., Ltd. seo Power by:www.300.cn

13405568899

13405568899 827352855@qq.com

827352855@qq.com Messages

Messages